mechanical refrigeration

What is mechanical refrigeration?

Mechanical refrigeration, often referred to simply as refrigeration or air conditioning, is a process by which heat is removed from a location using a human-made heat exchange system. In a data center, computer room air conditioning (CRAC) is the most common use of refrigeration.

Principles of mechanical refrigeration

The underlying physics principle of mechanical refrigeration is the first law of thermodynamics. This law states that energy -- or heat in this case -- cannot be created or destroyed, only transferred from one place to another, and that it requires work to cause the transfer of energy. In a refrigeration process, the heat energy is absorbed in one location where it is not wanted, and through a process, it is pumped to another location where the heat can be expelled or radiated away. The work energy required to cause the heat transfer is provided by a pump or motor, not from an electrical or chemical process, so it is referred to as mechanical refrigeration.

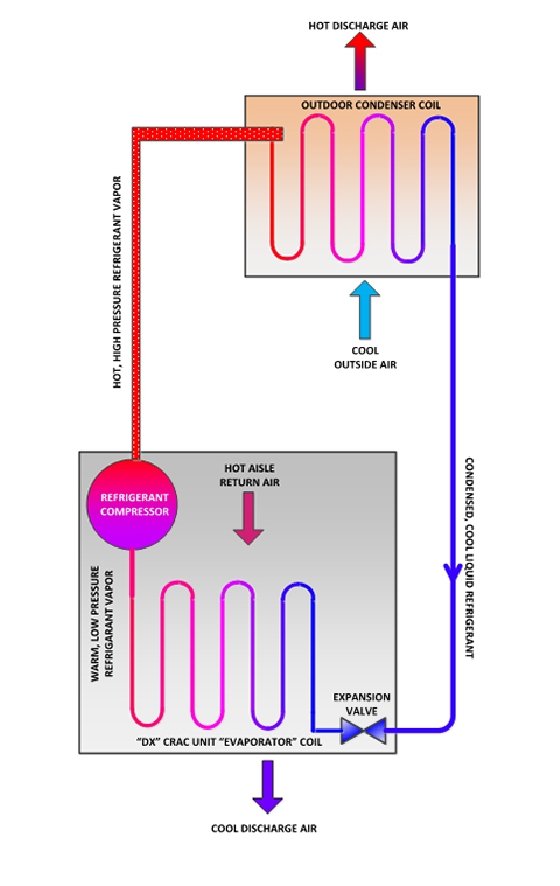

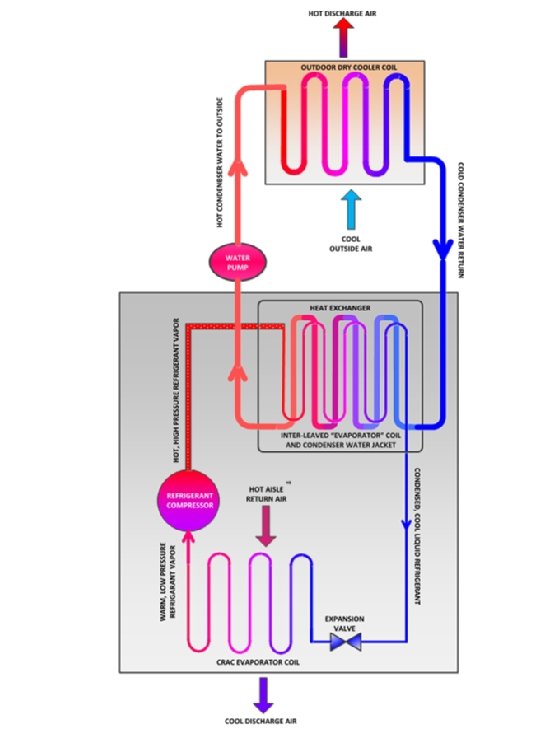

The most common form of mechanical refrigeration is the vapor compression cycle, also known as a reverse-Rankine cycle. It uses a refrigerant that is circulated to absorb and expel the heat. The refrigerant operates on the principle that heat is absorbed when a liquid boils or evaporates and that heat is released when a vapor condenses. The refrigerants have below-room temperature boiling points to enable a cooling effect.

In a typical vapor compression refrigerator, the high-pressure liquid refrigerant is first forced through an expansion valve. It then enters a lower pressure series of tubes called the evaporator, where the liquid refrigerant boils. The boiling action causes it to absorb heat from the air around the evaporator as it turns to a vapor. The heated vapor then goes through a compressor or pump that forces it into the higher-pressure condenser tubes or coil. In the condenser, the high pressure causes the refrigerant to condense back into a liquid, which expels the heat, typically to a radiator of some sort. The liquid refrigerant is now ready to go back through the expansion valve again and repeat the process.

An additional effect of refrigeration is that it reduces the humidity or dries the cooler air. This has many useful industrial applications. Systems must be designed to collect water condensation that forms on the evaporator coils. It is also possible that ice can form on the evaporator coils, causing performance issues.

Mechanical refrigeration in a data center

Waste heat is a major concern in data center heating, ventilation and air conditioning (HVAC) designs since electronics generate heat. Because data centers have many computers packed tightly together, they generate massive amounts of waste heat, much more than can be handled through passive means. Additionally, high humidity can damage computers. Therefore, mechanical refrigeration is required. If a data center or computer room is not actively cooled, it can quickly become so hot that the computer components can become damaged.

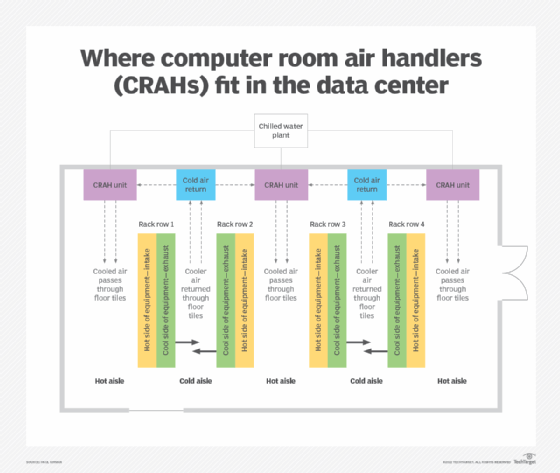

In traditional data center designs, the servers themselves are air-cooled and expel their heat into the surrounding air. A large CRAC unit cools and dehumidifies the air inside the data center. Typically, more than one CRAC unit is in each data center to enable redundancy and so that they can be maintained without causing excessive heat buildup.

In most cases, the CRAC unit forces cooled air into the raised floor of the data center. Perforated floor panels are strategically positioned so cool air comes up at the air intakes of the server racks. It is good practice that server racks are placed in aisles so that the inlets and outlets of their fans face each other, causing hot and cold aisles. The heated air is then taken in by air handlers in the ceiling.

In most small to midsize uses, the refrigeration evaporator is inside the data center. This can be in a single unit with the evaporator and condenser together in a self-contained unit with the hot air ducted to the outside. More often, a split system is used, where the condenser is located outside the data center and the refrigerant is pumped between the two separate units.

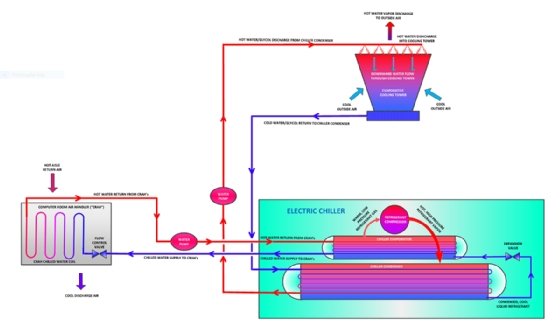

In large systems, the entire refrigeration system is located outside the data center in a chilling plant, and only cooled water, or glycol, is pumped to the data center. The chilled liquid is used by a computer room air handler (CRAH). The CRAH forces the hot air over the chilled water, thereby cooling the air. In some cases, the chilled liquid may be piped directly to server racks.

Environmental monitoring is important in data centers. This checks the overall temperature and humidity of the air and causes alarms if the metrics get too high. Additionally, water detectors are placed near CRAC units to alert if water accidentally overflows from them to prevent damage to the computers. These can be tied into a building management system.

There are several ways to measure the capacity of a mechanical refrigeration system. These can be given in kilowatts, kilojoules per second or British thermal units per hour -- or, in North America, as tons of refrigeration. The energy efficiency of a system can be given as a performance factor, coefficient of performance, energy efficiency ratio, seasonal EER or integrated EER.

Historically, 70 degrees Fahrenheit has been considered the optimal temperature for data centers. Some modern data centers may be kept at 80 degrees Fahrenheit as new equipment is less sensitive to temperature and it enables greater energy efficiency. The optimal humidity for a data center is between 40% and 50%.

Mechanical refrigeration future use, other forms of data center cooling

Mechanical refrigeration is by far the most common form of cooling in use today. Unfortunately, it requires a lot of electricity. Therefore, it is falling out of favor in large data center design. Its ubiquity and ease of use mean that it will continue to be used in small and midsize designs for many years to come, though.

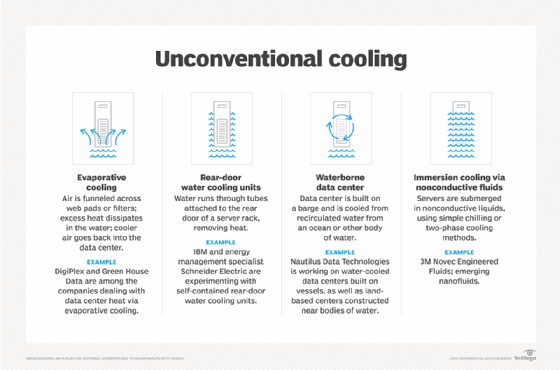

To reduce the environmental impact, some data centers may make use of water cooling or immersion cooling of the servers. The use of evaporative cooling towers is common in extremely large data centers due to its low energy use. A Peltier cooler may be used to remove heat using electricity from a specific computer component.

As data centers use more and more of the global energy each year, there are many initiatives to reduce the energy and natural resources needed to cool them. These can be net-zero or carbon-neutral energy use, reducing water use for cooling towers, waste heat recovery systems and passive cooling.

See also: a mechanical refrigeration system primer for admins and how to evaluate air cooling vs. liquid cooling for your data center.