IoT and digital twins: How they work together, with examples

IoT devices collect real-world data, while digital twins create virtual models using that data—together, they provide detailed insights to improve operations and predict issues.

In today's world, a single technology rarely stands alone. Often, a combination of different technologies and techniques unlocks true value for users.

That's the case with internet of things (IoT) and digital twins. Industries and organizations of all stripes are increasingly pairing the duo, recognizing their ability to improve efficiency, support sustainability, reduce downtime and lower costs.

Understanding IoT and digital twin technologies

IoT and digital twin technologies each have their own purpose. IoT exists in the physical world, while digital twins are virtual. Understanding these distinct technologies, their differences and how they work is critical to successfully combining the two.

What is IoT and how does it work?

IoT and specifically IoT devices define a category of internet-connected devices that span industries and deployments. IoT often includes embedded devices such as sensors, as do most machinery or industrial components. IoT operates inside manufacturing facilities and other smart buildings, and it's a core element of smart cities too.

IoT works because its embedded operating system can collect data. The IoT device also has some form of networking capability – Wi-Fi, cellular connectivity or LoRaWAN – to communicate and connect with the public internet.

What is a digital twin and how does it work?

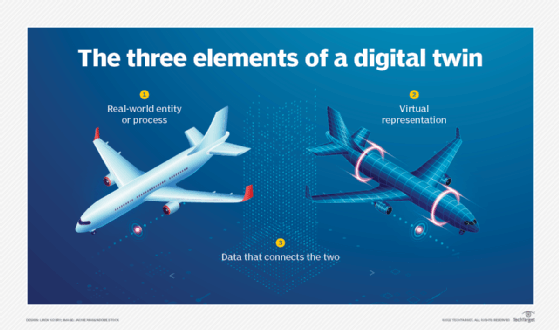

A digital twin is a virtual representation of a real-world entity, physical asset or process.

Some confuse the concept of a digital twin with a simulation, but they aren't identical. Unlike static simulations, digital twins use real-time data to mirror physical attributes throughout a product's life, operating as a virtual duplicate of the real-world entity or process.

How do they work together?

IoT devices stream data to many different sources. In this example, one of those sources is digital twin deployment. With the streaming data from the IoT device, the digital twin creates a virtual representation of the device, based on real-world information.

In fact, the digital twin, powered by data streaming from the IoT device, repeatedly produces highly detailed simulations and predictions about the device and its environment. This enables immediate updates to the digital twin's virtual representation, continuously supporting device optimization.

Benefits of combining IoT and digital twin technology

Time and again, organizations use IoT and digital twin technologies because of the proven advantages of their coupling. The combination's numerous benefits include:

- Real-time insights. Digital twins instantly use the data from devices to provide updates and insights.

- Preventive maintenance. The linking enables digital twins to forecast potential issues – and operators to perform maintenance – before a failure occurs, reducing downtime.

- Performance optimization. Digital twins simulate different operational scenarios, searching for and highlighting the most efficient configurations to raise performance.

- Energy usage and sustainability. IoT-powered digital twins impact energy usage and sustainability initiatives. The two technologies combine real-time energy monitoring and automated optimization based on usage patterns and environmental conditions.

- Data-driven decisions. With accurate simulations and predictions, organizations make better-informed decisions regarding design, production and operations.

- Risk management. A digital twin with IoT data helps risk management, identifying and quantifying potential failure scenarios and supporting business continuity. Organizations model various operational conditions, then test response strategies virtually.

Use cases and industrial examples of IoT digital twins

Today, IoT-powered digital twins deliver benefits across industries and in projects of all sizes, as seen in the following situations.

- Automotive. Among manufacturing verticals, global car makers use IoT-powered digital twins to improve both new-vehicle product design and existing production lines. Tesla, in particular, creates individual digital twins for every vehicle produced, using battery monitoring sensors, energy consumption meters, performance tracking devices and charging system monitors to enable over-the-air software updates and predictive maintenance.

- Aerospace. Multiple vendors in the aerospace industry use the technology to clarify performance issues and proactively handle preventive maintenance tasks. Rolls-Royce embraced the technology as part of the company's Blue Data Thread initiative.

- Manufacturing. Manufacturing digital twins integrates a host of IoT devices, including production line sensors and quality control systems. Siemens is among the many vendors using the technology to improve its manufacturing floor operations.

- Energy. Energy producers and distributors employ digital twin technology. General Electric, for example, uses it to monitor performance and optimize operations for its onshore wind turbines.

- Healthcare. Healthcare operators use technology to monitor and model patient health. Twin Health, for instance, uses wearable technology, such as glucose sensors and blood pressure monitors, to create individual patient metabolic models. The virtual representation expands patient treatment options.

- Smart cities. Smart city digital twins use distributed IoT sensor networks to monitor anything from downtown traffic to environmental conditions. Virtual Singapore, for example, enables real-time urban management and optimized transportation for the entire city-state.

Vendors offering IoT digital twin capabilities

With all these benefits and use cases for IoT digital twins, vendors see a wealth of opportunity. The market is projected to surpass $155 billion by 2030, a 34.2% increase, according to Grand View Research.

The chart below outlines some of the many vendors active in the space.

| Vendor |

Platform/Solution |

Key capabilities |

Website |

| PTC |

ThingWorx Industrial IoT Platform |

Low-code IoT development, AR/VR integration with Vuforia, industrial protocol adaptability with Kepware, digital twin modeling, rapid application development |

|

| Microsoft |

Azure Digital Twins |

Platform as a service, native Azure IoT Hub integration, spatial intelligence |

|

| AWS |

IoT TwinMaker |

Automated knowledge graph generation, 3D scene composition, IoT SiteWise integration, Kinesis Video Streams |

|

| Siemens |

Xcelerator (MindSphere) |

Product lifecycle management, AI-powered design, MindSphere IoT platform, Teamcenter integration, manufacturing digitalization |

|

| GE |

Predix/ Vernova |

Equipment performance optimization, predictive maintenance, aviation and power generation focus, industrial analytics, asset performance management |

|

| ABB |

ABB Ability |

Industrial automation integration, comprehensive device connectivity, process optimization, electrical systems integration |

|

| Nvidia |

Omniverse |

Real-time collaboration, advanced physics simulation, AI integration, metaverse applications, RTX computing |

|

| SAP |

SAP Cumulocity (formerly Leonardo IoT) |

Enterprise integration, IoT data management, business process integration, analytics and machine learning, industry-specific solutions |

https://www.sap.com/products/scm/partners/cumulocity-gmbh-cumulocity-platform-starter-edition.html |

(Editor's Note: These vendors appear in analyst rankings from ABI Research, Forrester, IDC MarketScape and Gartner.)

Sean Michael Kerner is an IT consultant, technology enthusiast and tinkerer. He has pulled Token Ring, configured NetWare and been known to compile his own Linux kernel. He consults with industry and media organizations on technology issues.