Getty Images/iStockphoto

Hidden issues complicate sustainability in IT manufacturing

Clare Hobby of TCO Development discusses how difficult it is to rate IT products' sustainability. But corporate buyers and consumers have the power to demand something different.

The issue of sustainability is becoming more vital in the IT industry.

Businesses and consumers are more aware of the energy consumption of computers, and manufacturers are eager to place "green" ecolabels on their machines.

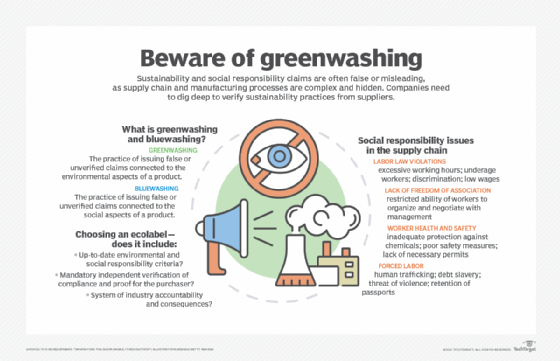

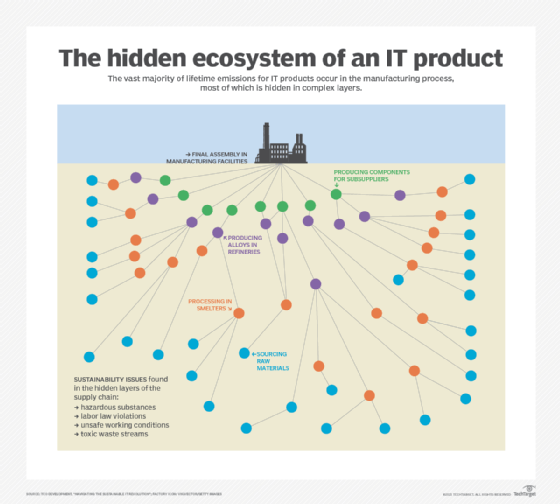

While interest from corporate buyers and consumers is rising, measuring sustainability can be more art than science. ERP vendors such as SAP and Infor have introduced products that help companies measure carbon emissions in business processes, but the products are relatively new and adoption is not widespread. IT products are also complex, built with sometimes thousands of components, so data from a product's supply chain can be obscured. And IT products are often subject to Greenwashing, which is a term used to describe misleading claims about the sustainable benefits of products.

TCO Development, based in Stockholm, has provided its TCO Certified sustainability certification for IT products for more than 25 years. TCO Development publishes sustainability certification standards every three to four years for IT products such as desktop computers, servers, data center products, display monitors and devices, according to the company.

In this Q&A, Clare Hobby, global director purchaser engagement at TCO Development, discusses some of the sustainability issues that affect the IT industry, and the power buyers have to change those processes.

How does TCO Development assess sustainability and social responsibility practices in IT industry manufacturing facilities?

Clare Hobby

Clare Hobby

Clare Hobby: Every product model is independently tested. We go into the factories through our verifiers and, through our system, we monitor what's going on and we hold them accountable. It's about reducing risk for corporate buyers, for public sector buyers and for consumers, but also gives them a tool that helps them access something that is otherwise invisible to them. They're expected to trust what the industry tells them because they have no other way of accessing these factors, right?

Do ecolabels help customers understand which products are made sustainably?

Hobby: There are literally hundreds of seals and labels as everybody's getting on the bandwagon of green or sustainable, but many of these labels don't have a lot backing them up. You're expected to just trust what you're being told, and if it's got a green leaf on it, it must be good. The problem with IT is that it's not bananas; it's so incredibly complex. Every computer has thousands of components and hundreds of manufacturing steps, so it's hard for purchasers to assess [sustainability claims].

What are the biggest sustainability issues in IT manufacturing?

Hobby: We did a study last year based on a series of laptop computers and found that between 75% to 85% of the total lifetime of carbon emissions happened in manufacturing. There's obvious worker impacts, human rights and ethical supply chains, so it's not like you can just think about energy consumption on the desktop. Because if you're thinking about it, then you haven't been able to impact the design phase or the manufacturing phase where most of the impact is.

The problem with this is that the IT industry has gotten good at selling us products frequently and doing it very profitably. We're all stuck in this three- to four-year replacement cycle in the corporate setting … and these machines are really made to last an awful lot longer.

Can consumers play a role in improving sustainability issues?

Hobby: If we're getting a new machine every three years, we're perpetuating that 80% emissions over and over again. As users, we need to be smarter at stopping that three-year lifecycle. So, the best thing we can do is to use products longer.

We have to rethink that whole business model. Can we do better with things like refurbishing or remanufacturing? We've got to find that sweet spot where we're using it longer, but we're also making sure it has a second life with another user. We can't keep doing this virgin manufacturing as often as we're doing it now, because that's where all the impact is. This is a time when users and buyers can start to really influence a different business model.

Will these measures increase costs or require major changes in the manufacturer's business models?

Hobby: The IT industry is still figuring out what this new business model looks like. We're big proponents of having those critical components be replaceable, but this has been a really problematic area for the industry because there are some things that are actually tricky to switch out. It's expensive, and the cost of the components doesn't make sense a lot of the time. They're really trying to figure this out.

What role can corporate buyers play?

Hobby: Buyers really need to get smart on this and raise their voices and use their dollars to ask for something different, but we're still figuring out what that is. The industry is really doing some good work in some spaces to try and figure this out, but too many buyers are waiting to think about these issues until they have the product in place. They have to think about it upfront. The conversation actually needs to happen in the [request for proposal or request for information] phase -- right at the beginning when you're talking to vendors, you need to signal that this stuff is important and you intend to use it longer. Also, now, some buyers are putting in a percentage of refurbished or remanufactured equipment as part of the tender.

So, the goal should be to get longer use out of IT products?

Hobby: Longer use is going to be critical. More replaceable components and right to repair are huge challenges, but we need to get over those barriers. If you look at the COVID-19 pandemic, supply chains for some components are strict right now, and you can't get certain chipsets. So, people have to feel confident that they can stretch the use of their products for the next pandemic, and the industry needs to get very serious about their role in the circular economy.

Editor's note: The following has been edited for clarity and length.

Jim O'Donnell is a TechTarget news writer who covers ERP and other enterprise applications for SearchSAP and SearchERP.