vasabii - Fotolia

The buzz: New 4-D printing gets itself together

And you thought 3-D printing was avant-garde? Get a load of this one-upper: The 4-D process prints parts that can assemble or repair themselves. That is, in theory.

With the plastic flowers and gun parts from 3-D printers still warm, researchers have added yet another dimension to additive manufacturing. The aim of 4-D printing is to make objects that can assemble themselves or adapt to the environment over time.

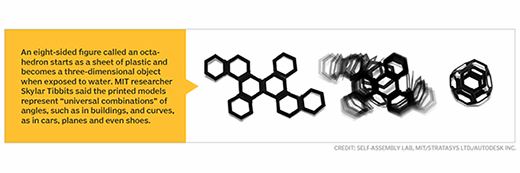

The buzz: The process works this way: Materials that have been programmed to respond to a stimulus such as heat, cold or moisture are printed using a 3-D printer. The particles in these substances form bonds, enabling, say, a printed cord of material to twist itself into a certain shape. Skylar Tibbits, director of Massachusetts Institute of Technology's Self-Assembly Lab, says 4-D printing can be used to produce "smart objects" that can adjust to external changes or repair themselves. For example, pipes could be designed to swell or contract to meet water demand -- or heal if they burst. Self-assembling or self-repairing technology could also be put to use in disaster areas or hostile environments such as space.

The reality: Though 4-D printing has seen some success in the lab -- Tibbits recently developed a sheet of material that folds itself into a box -- no one has used it to create real products. There's no data on how long a self-assembled product would hold up -- or whether it would perform as programmed to. If it pans out, the approach could revolutionize construction, carpentry and manufacturing -- and trigger massive job losses. For now, though, shape-shifting goods are still the stuff of science fiction.