printed circuit board (PCB)

What is a printed circuit board (PCB)?

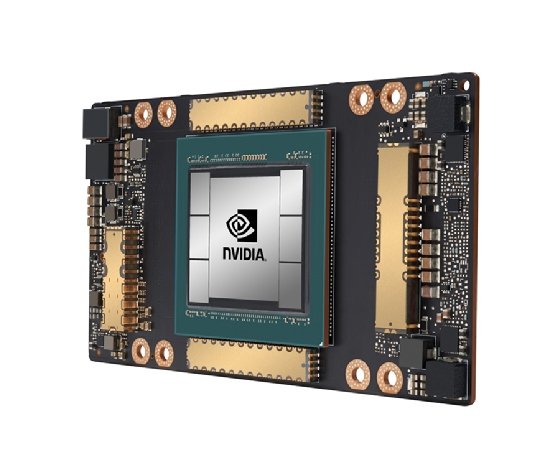

A printed circuit board (PCB) is a structure for assembling electronic components and their connections into a unified circuit that allows electrical current to pass between components. The PCB baseboard is typically made of a rigid nonconductive material, although it can also be built on a flexible base or on a base made up of both rigid and flexible materials. Electronic components such as diodes, inductors and transistors attach to the circuit board, and traces (electrical conduits) connect components.

Printed circuit boards support electronic devices of all types and sizes. For example, many consumer products contain PCBs, including laptops, tablets, smartphones and smartwatches, as well as appliances, entertainment systems and IoT devices. PCBs also drive communication and navigation systems and are found in industrial and medical equipment, automobiles, aircraft and sea vessels.

Printed circuit board layers

A PCB can be single-layer, double-layer or multilayer. Single-layer PCBs are typically used for simple electronic devices such as home appliances, while multilayer PCBs tend to be built for more complex hardware, such as computer graphics cards and motherboards. Double-layer PCBs allow for greater density than single-layer PCBs and are used for electronic devices such as automotive dashboards or LED lighting, for example.

A PCB's layer count is commonly based on its number of conductive layers. However, a PCB also includes other types of layers, which are laminated together in alternating patterns of conductive and insulating material. Today's PCBs always contain the following four types of layers:

- Substrate. This is the base, or core, layer. It is typically a rigid insulating material such as FR-4, a fiberglass/epoxy composite. In some cases, the substrate is a flexible material, usually plastic, which can fold or bend to accommodate space requirements. Flexible substrates can also withstand higher temperatures and other harsh conditions. Some PCBs use a combination of both rigid and flexible substrate materials.

- Conductive. This layer is usually made from a thin sheet of copper. On a single-sided (or single-layer) PCB, there is one conductive layer laminated to the substrate. On a double-sided (or double layer) PCB, there are two conductive layers, one on each side of the substrate. A multilayer PCB alternates between the substrate and conductive layers.

- Solder mask. The conductive layer is covered with a solder mask, a nonconductive material that gives PCBs their green color, although other colors can be used. The solder mask acts as an insulator for the underlying traces that are etched in the conductive material. The solder mask is also applied to the bottom of a single-sided PCB.

- Silkscreen. This layer is simply the labeling that is applied to the PCB after all the other layers have been added. The labeling can include numbers, letters, symbols or other information that indicates the various functions of each connection point. The labeling is usually white, but other colors can be used.

A PCB is made up of a mix of these four types of layers. The mix and its organization varies depending on the PCB's purpose. A single-layer PCB includes one of each of these four layers. A double-layer PCB includes one substrate, but two of each of the other types of layers. A multilayer PCB will contain a mix of conductive and nonconductive layers, although the exact organization can vary. In some cases, a multilayer PCB might also use prepreg as a layer. Prepreg is a dielectric material that's sandwiched between two core layers or between core and conductor layers.

Printed circuit board components

PCB components use one of two methods to connect to the board: through-hole or surface-mount. Through-hole components have connecting wires (leads) that plug into holes in the board. The leads are soldered to the other side of the board. Surface-mount components are soldered directly to the same side of the board. Today's PCBs tend to favor surface-mount components because they require less space and are more efficient, although they're more difficult to assemble.

The PCB components connect to each other via traces, which facilitate communications between the components. The traces are created from the conductive layer through a process called etching, which removes all the copper from the conductive layer except what is needed for the traces.

A PCB can include a range of components, which vary depending on the board's purpose. Some of the more common types of components include the following:

- Battery. Provides voltage to the PCB's circuit, although many PCBs receive their power from external sources.

- Capacitor. Holds electrical charge and then releases it when it is needed in the PCB's circuit.

- Diode. Ensures that the current flows in only one direction, preventing it from flowing in the wrong direction.

- Inductor. Stores energy in the form of a magnetic field, which can help control the fluctuations in the electric current flowing through the PCB.

- Resistor. Limits or regulates the flow of electric current in the PCB's circuit by generating resistance to the current's flow.

- Sensor. Detects input from the physical environment -- such as vibration, motion, acceleration or infrared light -- and responds to that input by generating a corresponding signal.

- Switch. Switches the current on or off as it passes through the PCB's circuit.

- Transistor. Amplifies or switches the electronic signal passing through the PCB's circuit.

Many of today's PCBs adhere to a high-density interconnect (HDI) design, which incorporates a higher wiring density than traditional PCBs. HDI circuit boards require less space and can accommodate more components. The design also makes it possible to create more compact PCBs, which weigh less and require fewer materials. The HDI design is well-suited for use cases where space is an important factor, such as smartphones, home appliances or medical implants.

Learn the major types of server hardware and their pros and cons and explore the differences between CPU, GPU and DPU.