What is IIoT (industrial internet of things)?

The industrial internet of things (IIoT) is the use of smart sensors, actuators and other devices, such as radio frequency identification tags, to enhance manufacturing and industrial processes. These devices are networked together to collect, exchange and analyze data. Insights gained from this process aid in more efficiency and reliability. Also known as the industrial internet, IIoT is used in many industries, including manufacturing, energy management, utilities, oil and gas.

IIoT uses the power of smart machines and real-time analytics to take advantage of the data that dumb machines have produced in industrial settings for years. The driving philosophy behind IIoT is that smart machines are better than humans at capturing and analyzing data in real time. They're also better at communicating important information that can be used to drive business decisions faster and more accurately.

Connected sensors and actuators let companies identify inefficiencies and problems sooner, saving time and money while also supporting business intelligence efforts. In manufacturing specifically, IIoT has the potential to provide quality control, sustainable and green practices, supply chain traceability and overall supply chain efficiency. In an industrial setting, IIoT is key to processes such as predictive maintenance, enhanced field service, energy management and asset tracking.

Why is IIoT important?

In addition to the many transformational improvements IIoT makes in terms of operational efficiency and performance, there are several other reasons it's important, including the following:

- Real-time monitoring. To ensure that manufacturing and other industrial systems are performing properly, it's essential to monitor them in real time. Monitoring can flag components that might be underperforming and trigger preventive maintenance.

- Data collection and analysis. IIoT devices collect and analyze a large amount of data that can identify ways to improve performance, better manage inventory and energy use, and provide insights for better decision-making.

- Health and safety. These devices can identify working conditions that might be potentially hazardous to employees' health and safety. IIoT data can be instrumental in improving overall environment management and sustainability activities by identifying conditions potentially damaging to the environment.

- Supply chain management. IIoT technology contributes to supply chain optimization. It can track assets and inventory, transportation of supplies and finished goods, and identify situations that could disrupt logistics.

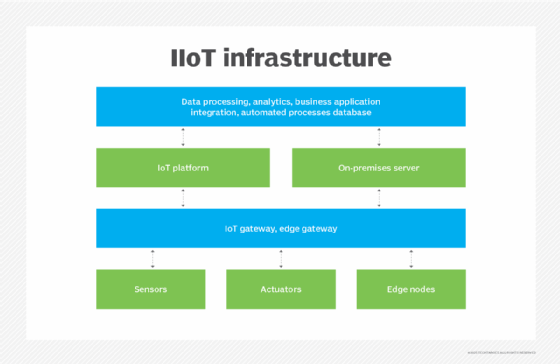

How does IIoT work?

IIoT is a network of intelligent devices connected to form systems that monitor, collect, exchange and analyze data. Each industrial IoT ecosystem consists of the following:

- Connected devices that sense, communicate and store information about themselves.

- Public and private data communications infrastructure.

- Analytics and applications that generate business information from raw data.

- Storage for the data that the IIoT devices generate.

- People.

These edge devices and intelligent assets transmit information directly to the data communications infrastructure, where it's converted into actionable information on how a certain piece of machinery is operating. This information can be used for predictive maintenance, as well as to optimize business processes.

What is the difference between IoT and IIoT?

The internet of things and IIoT have many technologies in common, including cloud platforms, sensors, connectivity, machine-to-machine communications and data analytics. However, they're also used for different purposes.

IoT systems connect devices across multiple verticals, including agriculture, healthcare, enterprise, consumer, utilities, government and cities. IoT technology includes smart devices, fitness bands, home appliances and other applications that generally don't create emergency situations if something goes amiss.

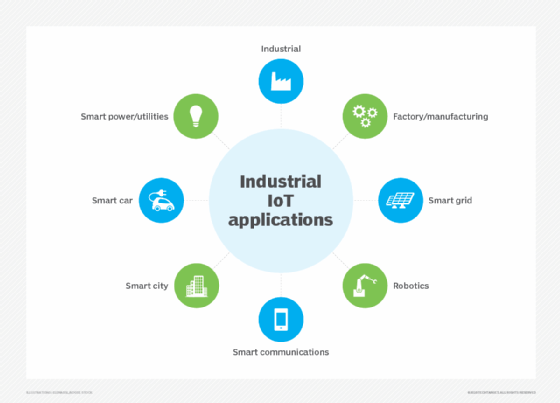

IIoT applications, on the other hand, connect machines and devices in sectors such as oil and gas, utilities and manufacturing. System failures and downtime in IIoT deployments can result in high-risk or life-threatening situations. IIoT applications are also more concerned with improving efficiency, health or safety versus the user-centric nature of IoT applications.

Which industries are using IIoT?

Many industries use IIoT, including the following:

- Automotive. IIoT is used to proactively maintain the industrial robot systems the automotive industry uses. It can spot potential problems before they can disrupt production. The industry also uses IIoT devices to collect data from customer systems, sending it to the company's systems. That data is then used to identify potential maintenance issues.

- Agriculture. Industrial sensors collect data about soil nutrients, moisture and other variables, helping farmers optimize crop production.

- Oil and gas. Some oil companies maintain a fleet of autonomous aircraft that use visual and thermal imaging to detect potential pipeline problems. This information is combined with data from other types of sensors to ensure safe operations.

- Utilities. IIoT is used in electric, water and gas metering, as well as for the remote monitoring of industrial utilities equipment such as transformers.

What are the benefits of IIoT?

IIoT devices used in the manufacturing industry offer the following benefits:

- Predictive maintenance. Organizations can use real-time data generated from IIoT systems to predict when a machine needs to be serviced. That way, the necessary maintenance can be performed before a failure occurs. This can be especially beneficial on a production line, where the failure of a machine might result in a work stoppage and huge costs. By proactively addressing maintenance issues, an organization can achieve better operational efficiency.

- More efficient field service. IIoT technologies help field service technicians identify potential issues in customer equipment before they become major issues, enabling techs to fix the problems before they affect customers. These technologies also provide field service technicians with information about which parts they need to make a repair. This ensures technicians have the necessary parts with them when making a service call.

- Asset tracking. Suppliers, manufacturers and customers can use asset management systems to track the location, status and condition of products throughout the supply chain. The system sends instant alerts to stakeholders if the goods are damaged or at risk of being damaged, giving them a chance to take immediate or preventive action to remedy the situation.

- Increased customer satisfaction. When products are connected to IoT, the manufacturer can capture and analyze data about how customers use their products, enabling manufacturers and product designers to build more customer-centric product roadmaps.

- Improved facility management. Manufacturing equipment is susceptible to wear and tear, which can be exacerbated by certain conditions in a factory. Sensors can monitor vibrations, temperature and other factors that could lead to suboptimal operating conditions.

Is IIoT secure?

Early on, manufacturers created IoT devices with little regard for security, resulting in the perception that IoT devices were inherently insecure. Given the similarities between IoT and IIoT devices, it's worth considering whether IIoT devices are safe.

As with any other connected device, IIoT devices must be evaluated on a device-by-device basis. It's entirely possible that one manufacturer's device is secure while another manufacturer's isn't. Even so, security is a bigger priority among device manufacturers than ever before. For example, security methods used in IIoT might include multifactor authentication, end-to-end encryption and the creation of custom 33 authorization levels.

In 2014, several technology companies, including AT&T, Cisco, General Electric, IBM and Intel, formed the Industrial Internet Consortium (IIC), which was rebranded as the Industry IoT Consortium in 2020. Although this group's primary objective continues to accelerate the adoption of IIoT and related technologies, it's made security a priority, even going so far as to form a security working group. The IIC's other working groups include technology, liaison, marketing, industry and digital transformation. The group has also created the Industrial IoT Networking Framework to provide guidelines on designing and deploying IIoT networking products.

What are the risks and challenges of IIoT?

The biggest risks associated with IIoT use pertain to security. It's relatively common for IIoT devices to continue using default passwords, even after they've been put into production. Similarly, many IIoT devices transmit data as clear text. These conditions can make it relatively easy for an attacker to intercept the data coming from an IIoT device. Similarly, an attacker could take over an insecure IIoT device and use it as a platform for launching an attack against other network resources.

Security and device management are major challenges for those who are responsible for an organization's IIoT devices. As an organization adds more IIoT devices, it becomes increasingly important to adopt an effective device management strategy. More specifically, organizations must be able to positively identify IIoT devices to prevent the use of rogue devices. Establishing a means of identifying each individual device is also crucial for tasks such as replacing a failed device or performing a device refresh.

Patch management presents another challenge with IIoT devices. It's becoming more common for device manufacturers to issue periodic firmware updates. Organizations must have an efficient way to check devices to see if they have the latest firmware installed and deploy new firmware if necessary. In addition, such a tool must adhere to the organization's established maintenance schedule, so it doesn't disrupt operations.

IIoT regulations, standards and frameworks

Several regulations have been developed to address the growing world of IIoT. The following are key examples:

- European Union Cybersecurity Act. This EU law defines security certification requirements for IIoT devices.

- IoT Cybersecurity Improvement Act of 2020. This U.S. rule defines security requirements for IIoT devices used by the federal government and in the private sector.

- UK Product Security and Telecommunications Infrastructure Act. This regulation provides specifications for secure IIoT devices, patch management and disclosure of device vulnerabilities.

- EU General Data Protection Regulation. The GDPR delineates security requirements, such as encryption and personal consent, for IIoT devices that collect personal data.

Standards and frameworks that encompass IIoT include the following:

- International Organization for Standardization/International Electrotechnical Commission (ISO/IEC) 27001. This is a global cybersecurity standard for information security management systems and applicable to IIoT devices.

- ISO/IEC 30141:2018. This standard defines the architecture for secure, scalable IIoT systems.

- ISO/IEC TS 30149:2024. This one defines trust requirements for IoT and IIoT systems.

- National Institute of Standards and Technology Special Publication 800-183. This defines U.S. guidelines for IIoT security best practices.

- EU Agency for Cybersecurity (ENISA). Best practices for firmware management, access authentication and data encryption as defined by the EU.

What are IIoT applications and examples?

IIoT technology can be used in a variety of applications. For example, ABB, a power and robotics company, uses connected sensors to monitor the maintenance needs of its robots to prompt repairs before parts break.

Likewise, commercial jetliner maker Airbus launched what it calls the factory of the future, a digital manufacturing initiative to streamline operations and boost production. Airbus integrated sensors into machines and tools on the shop floor and outfitted employees with wearable tech, such as industrial smart glasses, aimed at reducing errors and enhancing workplace safety.

Another robotics manufacturer, Fanuc, has used sensors in its robotics, along with cloud-based data analytics, to predict the imminent failure of components in its robots. Doing so enables the plant manager to schedule maintenance at convenient times, reducing costs and averting potential downtime.

Magna Steyr, an Austrian automotive manufacturer, is using IIoT to track its assets, including tools and vehicle parts, as well as to automatically order more stock when necessary.

IoT and 5G

5G is the newest standard for mobile networks. It was specifically designed to deliver fast data throughput speeds with low latency. 5G supports download speeds of up to 20 Gigabits per second with submillisecond latency.

The emergence of 5G is expected to drive greater use of IIoT devices in two main ways. First, 5G's high throughput and low latency make it possible for devices to share data in real time. Previously, this was only possible when the devices were located on private networks with high-speed connectivity. This real-time connectivity could support use cases such as driverless cars and smart cities.

The other way 5G affects IIoT adoption is that it will likely result in device proliferation. Industrial operations could use thousands of 5G-connected devices. The technology's high speed and low latency also mean we'll likely see IIoT devices used in remote sites where lack of high-speed connectivity previously made IIoT use impractical.

What are Industry 4.0 and 5.0?

IIoT emerged from two important initiatives: Industry 4.0 and 5.0. Industry 4.0, launched in 2011, established the foundation that's being realized in IIoT and other advanced industrial automation technologies.

Also, called the fourth industrial revolution, Industry 4.0 focuses on digitization and automation of manufacturing and industrial processes. Key attributes of it are smart factories, networked IoT devices, artificial intelligence (AI) and machine learning, and cloud technology. The main goals are to develop industrial exosystems that improve productivity and efficiency, automate repetitive functions and perform tasks in a secure environment.

Introduced in 2021, Industry 5.0 builds on 4.0 technologies, shifting the focus to human-centric innovation, sustainability and resilience. Key attributes include greater human-machine interaction, ethical issues like fairness and accountability, greater use of sustainable practices, increased resilience and survivability of systems, and a greater focus on data privacy and compliance.

Both approaches are still in place and serve as the foundations for IIoT and other advanced industrial systems and applications.

What is the future of IIoT?

Cognizance Market Research predicts the global IIoT market will reach $361 billion by 2032. The key technologies affecting the market are AI, machine learning, natural language, edge computing, blockchain and 5G, as well as digital twins, also known as virtual replicas, of industrial automation assets.

IIoT devices will continue to play a major role in digital transformations, especially as organizations attempt to digitize production lines and supply chains. Big data analytics is expected to evolve to incorporate IIoT data, so companies can detect changing conditions in real time and respond accordingly.

Learn more about IIoT use cases and real-time automated decision-making in manufacturing.