Getty Images/iStockphoto

9 benefits of MRP software

MRP and MRP II software can offer multiple benefits to manufacturers. Learn how manufacturing companies can use them to potentially improve key production processes.

Supply chain leaders are always looking to increase manufacturing efficiency, and material requirements planning software can potentially help them do so.

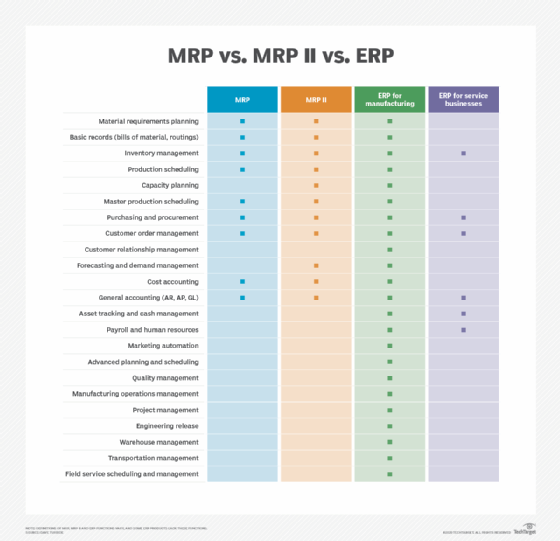

MRP helps ensure that manufacturers have the right materials available at the right time. MRP II extends the concept of MRP by supporting key capabilities, such as automation, workforce resources, inventory management and QA, among others.

Managing the complex, interdependent manufacturing processes can be challenging, and MRP and MRP II software can potentially help. Here are some of the benefits of MRP software.

Benefits of MRP and MRP II systems

Some advantages for manufacturers apply to both MRP and its later incarnation, MRP II. They include the following benefits.

1. Fulfills customer demand and product forecasts

Customer order levels and requirements drive the MRP process. When a retailer, wholesaler, intermediary or other customer requires products, MRP software uses these demands to schedule and manage critical parts of the manufacturing process.

Some MRP systems can also forecast demand. These MRP predictions can support manufacturers accurately estimating future needs and planning accordingly, helping the company meet production targets and schedules.

2. Improves product availability

Manufacturers can only create products if they possess the raw materials, and they can use MRP software to make sure they have the parts and components to create finished goods.

An MRP system examines three inventory management areas to determine material requirements:

- Bill of materials. A bill of materials is a master list of every part and component needed to manufacture an item.

- On-hand inventory. On-hand inventory is the quantity of each part and component currently in stock for an item.

- Outputs from master production scheduling. These outputs contain detailed information about manufacturing requirements.

By focusing on these three areas, MRP software can identify gaps and place orders for parts.

3. Reduces product manufacturing and delivery lead times

Customers expect to receive finished products shortly after ordering them, and MRP software can help speed up production by providing the required information about which parts to order and when.

This data can help avoid the need to wait for components before running the production line.

4. Minimizes manufacturing waste and lowers costs

MRP software can help reduce manufacturing waste and costs. The software achieves this in the following ways:

- Potentially reduces costs associated with managing large amounts of inventory by preventing a manufacturer from buying too much.

- Reduces inventory spoilage and wasted materials.

- Potentially decreases product manufacturing expenses.

5. Improves customer service

Strong customer relationships are essential for manufacturers, and MRP software can help improve customer service by ensuring product availability.

In addition, MRP software's reduction of lead times can help ensure that products are available during peak seasons, such as the holidays.

Benefits of software for MRP II systems

MRP II was created in the 1980s by using MRP as a jumping-off point. Since MRP II software has more capabilities, it can benefit manufacturers in several different ways than MRP.

6. Improves resource allocation

MRP software focuses on managing inventory, while MRP II software enables manufacturers to allocate resources more efficiently, potentially increasing productivity.

MRP II does so by carrying out the following:

- Optimizing workforce resources so employees are efficiently deployed on production lines.

- Minimizing downtime through regular equipment maintenance.

- Identifying ideal manufacturing capacity for each production line.

- Analyzing production rates so product manufacturing is properly scheduled.

7. Automates tasks to free up employees

MRP II software can integrate with robotics and other production line automation systems.

This capability can potentially reduce employee workload since they have fewer tasks to carry out.

8. Reduces product defects

QA is the testing of products for manufacturing defects and is an important part of manufacturing.

MRP II software integrates QA across production lines, enabling quick identification of faulty products and insight into the causes of manufacturing defects. This helps manufacturers deliver high-quality products and further reduce waste.

9. Identifies growth opportunities

Reporting capabilities can help improve manufacturing operations. MRP II software can report on all aspects of a production line, helping support production planning and enabling leaders to make better business decisions because they can analyze data from the MRP II software.

MRP II's reporting capabilities can also potentially increase profit margins since they can provide insight into future growth areas.