What is IoT data analytics?

Internet of things (IoT) data analytics is a comprehensive method of collecting, storing, processing, analyzing and, ultimately, presenting the vast amounts of data culled from IoT devices. Its application considers past, present and future real-world use cases or activities -- or some combination of the three.

Regardless of the mix, all IoT analytics jobs share the same underlying goal: to help business and technology leaders spot opportunities for operational improvement and make better-informed decisions. Measurable IoT analytics benefits include cost reduction, product quality improvement, more efficient use of time and materials and faster responses to market changes and opportunities.

Types of IoT analytics

There are four principal types of, or approaches to, IoT data analytics:

- Historical, or descriptive, analytics.

- Real-time, or diagnostic, analytics.

- Predictive analytics.

- Prescriptive analysis.

Here's a closer look at their use cases -- some unique and others interrelated.

Historical analytics

Historical analytics, or descriptive analytics, examines IoT data gathered over time to spot trends and find patterns. A business then evaluates behaviors in systems or environments to make objective determinations about their accuracy, efficiency or appropriate use. Historical analytics identifies valuable -- and often overlooked or undetected -- data patterns and relationships.

For example, a smart city collects data about traffic patterns and road conditions to understand the durability and performance of its transportation infrastructure. Such data helps determine road and bridge longevity, leading to improved repair and upgraded strategies.

Real-time analytics

Real-time analytics, or diagnostic analytics, immediately identifies anomalies or deviations from the norm, improving business response to unforeseen events or conditions. Real-time data combines with historical data to produce a more comprehensive data set for analysis.

For example, a manufacturing company uses smart sensors on its factory floor to measure each machine's physical activities. These IoT devices recognize malfunctions that disrupt manufacturing workflows or pinpoint mechanical anomalies that create product quality problems.

Predictive analytics

Predictive analytics uses patterns in historical and real-time data to forecast conditions, incidents or issues. Predictive analytics often combines with advanced computing capabilities, such as statistical modeling and machine learning (ML).

For example, an electric utility uses sensors and smart meters to collect data on energy consumption, predicting future energy demands based on season, weather, time of day and other factors. This optimizes energy production and distribution across its grid.

Prescriptive analysis

Prescriptive analysis, a variation of predictive analytics, provides solutions, suggests optimizations or offers alternatives to capitalize on collected IoT data. Prescriptive analysis uses both historical and real-time data and employs advanced ML algorithms and mathematical models.

For example, a retailer combines data from inventory systems, sales history and weather forecasts to determine optimal inventory levels -- and even pricing strategies -- for each product based on time of year, demand and competing products.

Mixing analytical approaches

Any motivated organization has the capacity to employ one or all of these approaches depending on business needs and goals. However, the types and amounts of available IoT data directly affect analytical capabilities.

For example, a business seeks historical analytics and therefore needs to collect, store and protect IoT data over long periods. By comparison, a neighboring business needs real-time analytics and alerts, so it wants relevant sensor data that determines system functionality immediately.

5 steps of IoT data analytics

IoT data analytics is a process, and each of the following steps has multiple aspects -- with some crossover -- that require scrutiny from business and technology leaders:

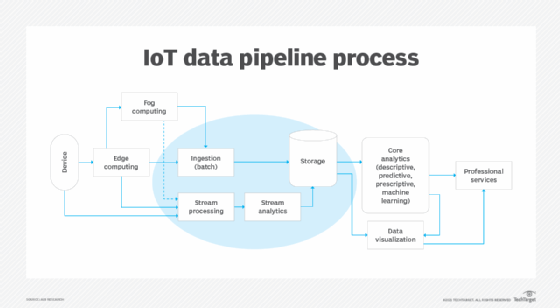

- Collection. Data generated by IoT devices is gathered from across a shared network and stored. IoT data collection generates tremendous network traffic depending on the number of IoT devices, the types of data generated and the data's urgency. Data is structured, unstructured or mixed. In most cases, it is collected and stored at the edge -- closest to the data's origin. This reduces network bandwidth and latency issues, as well as adding some data processing prior to analysis.

- Storage. Collected IoT data requires extensive storage capacity, especially if the data is retained for a prolonged period. As a significant business asset, it demands protection from unauthorized access, tampering, theft and misuse, guided by regulatory and business continuity obligations. Similarly, backup and other data protection measures safeguard against loss due to malfunctions or damage. In most cases, raw IoT data is stored at the edge near the IoT devices.

- Processing. Processing is a preparatory step addressing IoT data quality. Diverse devices generate IoT data, and this raw data must be cleaned, filtered, normalized and transformed into a useful and consistent format. This step achieves the following:

-

-

- Removes noise, such as outlying values.

- Manages missing data in a constructive and meaningful way.

- Ensures all data uses the same format or level of precision.

-

Some or all IoT data processing is performed through an IoT gateway located at the edge, again near IoT devices and any stored raw data. Processed data might be sent across a greater network to a data center for analysis.

- Analysis. Stored data is prepared and moved across a network, such as the internet, to a centralized location, such as a public cloud or local data center, where computing resources perform extensive data analyses. Here, the processed data undergoes detailed analysis -- descriptive, diagnostic, predictive, prescriptive or some combination -- based on the types, amounts and purpose of data collected.

- Presentation. The analyzed data is then presented to business and technology professionals in an easily understood format. The analysis typically includes reports, dashboards, graphs or other visualizations that help leaders make informed decisions, respond to specific events or introduce prescriptive suggestions.

Benefits of IoT data analytics

IoT data analytics offers several potential benefits to an enterprise, including the following:

- Faster response times. IoT analytics spots potential problems or issues -- sometimes long before a disruptive event occurs. Businesses use these analyses to perform maintenance or schedule prompt remediation, mitigating downtime and preserving the user experience.

- Faster time to market. By spotting relationships and predicting demand, IoT analytics develops and enhances products much more quickly than traditional design cycles. Products reach the market in less time, increasing an organization's revenue and competitive advantage.

- Increased revenue. IoT analytics identifies potential revenue opportunities, including unfulfilled product demand, optimized pricing and enhanced personalization. Once addressed, each area adds value to customers, users and partners, driving business revenue.

- Lower costs. IoT analytics reduces costs through improved resource allocation, streamlined operations and better issue management, from averted downtime to more effective maintenance practices.

- Enhanced quality. IoT analytics gathers information about product design, supply chain resources, product manufacturing and business outcomes. This data helps the organization find and reduce defects, improve consistency in products and services, satisfy customers with superior quality and thereby burnish the brand.

Challenges with IoT data analytics

IoT analytics delivers powerful benefits, yet business and technology leaders must recognize several critical challenges associated with IoT technology, including the following:

- Complexity. IoT deployments are demanding. First, they require the best IoT devices and their proper installation, configuration and ongoing management, including routine maintenance such as battery replacement and firmware updates. Other necessities include establishing a dedicated IoT network, plus building the computing and storage infrastructure required to generate the analytics. Success depends on extensive staff expertise, a clear business vision and steady support from all management levels.

- Scalability. Large IoT deployments typically grow more complex over time. Any IoT design demands careful consideration of both its current effectiveness and its scalability. Consider additional devices needed in the future and how to integrate and manage those new devices effectively. And, as data volume grows, it's vital to determine when the quantity of data being processed and analyzed begins to limit performance.

- IoT effectiveness. IoT demands a clear and well-supported purpose or use case, but business needs and conditions change. Business and technology leaders must oversee the IoT infrastructure and ensure its outcomes remain relevant and effective, often using objective metrics such as data loss or network latency. Select meaningful metrics. Watch the metrics over time. Correct any waning IoT analytics.

- Data quality. Data from IoT devices is often lost, corrupted or unusable due to device malfunctions, network issues or incompatible formats. An accurate, reliable and consistent IoT infrastructure features regular measurement, review and correction of data quality issues.

- Security. IoT data is a sensitive asset with tangible business value. Sometimes it includes personal data collected from a wearable device. As such, IoT data demands protection. Encryption, access control and reporting, authentication, acceptable use policies and backup and restoration are among proven security techniques. IoT data is typically subject to the same regulatory compliance and business continuity considerations as other sensitive business data.

Real-world applications of IoT data analytics

Enterprises employ IoT analytics across a wide range of real-world applications. The following are some common examples.

Supply chain logistics

IoT devices gather a variety of transportation vehicle data, including distance traveled, starts and stops, fuel used and idle times. This logistics data is collected and analyzed from all vehicles to gauge the efficiency of each, the routes traveled and subsequent maintenance needs. Analytics then predicts and schedules preventive vehicle maintenance and prescribes optimizations to save time, fuel and wear. Success is measured by comparing transport time, fuel use and maintenance costs without IoT analytics to the same parameters with IoT optimizations.

Manufacturing and retail inventory

IoT devices track inventory levels -- both components and finished goods. IoT analytics combines a grasp of current inventory levels with historical and predicted sales data, then pairs that information with a knowledge of supply chain logistics and manufacturing operations to optimize inventory. Components are ordered and delivered just in time for manufacturing to schedule and use them, then stock enough finished goods to reach market for sale. This reduces waste, limits inventory costs and increases manufacturing capacity.

Agriculture

IoT analytics buoys traditional businesses, including farming. IoT sensors measure soil conditions, such as moisture level; track available resources, such as fertilizer; and oversee farming vehicle locations. IoT analytics combines this tangible data with seasonal historical weather data, weather forecasts and data about pests and crop health. Analytics then produces suggestions to hone irrigation, alter fertilizers, administer pest control strategies and assign farm vehicles to perform tasks at the proper time, yielding the largest and healthiest crop.