What is supply chain visibility and why is it important?

Supply chain visibility (SCV) is the ability to track parts, components, raw materials or products as they move from the manufacturer to the final destination. It provides real-time insights into the supply chain, helping businesses monitor operations, optimize logistics and improve decision-making.

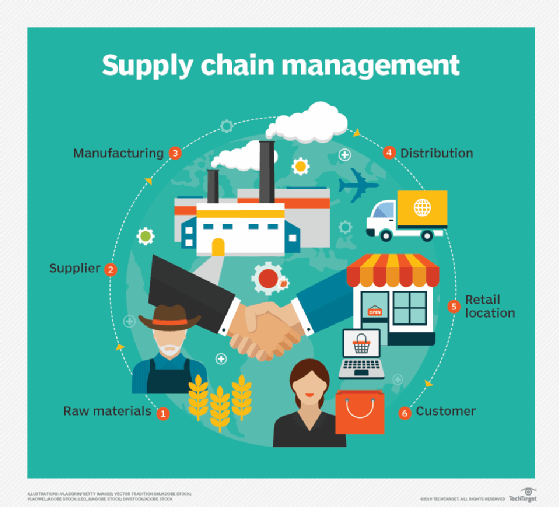

The primary goal of SCV is to increase transparency across the supply chain, ensuring that all stakeholders -- suppliers, manufacturers, distributors, retailers and customers -- have access to accurate and timely data. This visibility helps organizations mitigate risks, improve efficiency, enhance compliance and proactively respond to disruptions.

With the globalization of supply chains and growing complexity of logistics networks, achieving full supply chain visibility has become a priority for businesses across industries.

Why is supply chain visibility important?

Supply chains are complex, multi-tiered and interconnected. Without visibility, organizations lack control over operations, leading to inefficiencies, delays and disruptions. SCV is essential for ensuring supply chain agility, reducing risks and meeting customer expectations.

This article is part of

Guide to supply chain management

Some expected benefits of SCV include the following:

- Improved operational efficiency. Real-time tracking allows businesses to identify bottlenecks, optimize processes and minimize delays in production and delivery.

- Enhanced decision-making. Data-driven insights help companies forecast demand, allocate resources effectively and reduce excess inventory costs.

- Risk mitigation. SCV enables proactive risk management by identifying potential supply chain disruptions such as delays, supplier failures or geopolitical issues before they impact operations.

- Competitive advantage. Businesses with greater SCV can respond faster to market changes, reduce lead times and gain competitive advantage.

- Regulatory compliance. SCV helps organizations with regulatory compliance by helping them comply with industry regulations and trade policies, ensuring accurate record-keeping and traceability for audits and legal requirements.

- Increased customer satisfaction. Customers expect faster deliveries and real-time updates on their orders. SCV helps businesses meet these expectations, improving loyalty and trust.

How does supply chain visibility work?

SCV relies on integrated technologies such as data analytics and automation tools to provide end-to-end transparency. Key components of SCV include the following:

- Real-time tracking and monitoring. Using IoT sensors, RFID tags, GPS tracking and blockchain technology, companies can monitor goods in real time.

- Data integration and centralization. SCV platforms integrate data from multiple sources, including warehouse management systems (WMSes), ERP software and transportation management systems (TMSes).

- Predictive analytics and AI. Advanced AI-driven analytics helps companies forecast supply chain trends, predict potential delays and recommend alternative routes or suppliers to mitigate risks.

- Cloud-based supply chain management software. Cloud-based SCV enables real-time data sharing across supply chain partners, ensuring seamless collaboration and transparency.

- Blockchain for supply chain traceability. Blockchain technology enhances traceability, security and accountability by creating an immutable ledger of every transaction within the supply chain.

Supply chain visibility software and technology

SCV is typically a part of an ERP system. However, SCV has recently become even more integral as companies have increased the outsourcing of supply chain planning and, therefore, lost some visibility and control over it.

SCV, empowered by supply chain management technology, improves these issues by delivering real-time logistics data and insights into various aspects of the supply chain.

So, for example, through this technology, a company might review metrics that indicate impending supply chain shortages before they become severe and find ways to adapt, remove bottlenecks or reposition to meet goals, compliance requirements and delivery obligations.

Aspects of supply chain visibility data

Increasing supply chain visibility through data encompasses a variety of data collection activities. The following are some of the common data collected in SCV:

- Order status. Real-time visibility of cargo movement through the supply chain ensures operational efficiency, as the company knows when to expect the delivery of goods from the distributors.

- Auditing records. This includes various compliance and regulatory information throughout the supply chain. This is critical for ensuring that business processes are conducted lawfully.

- Shipping details. This includes real-time data on the shipment of goods. Through SCV software, this can be shared by all the relevant stakeholders at once.

Challenges in achieving supply chain visibility

Despite its benefits, many companies struggle with achieving full supply chain visibility due to data silos, outdated systems and lack of integration. Here are some common SCV adoption and implementation challenges:

- Data fragmentation and inconsistent information. Many organizations rely on disparate systems that do not seamlessly communicate with each other, leading to gaps in visibility.

- Lack of real-time insights. Delayed or inaccurate data collection can prevent companies from responding quickly to disruptions.

- Cybersecurity and data privacy risks. As supply chains become more digitalized, companies must ensure strong cybersecurity measures to protect sensitive data.

- Resistance to technology adoption. Many companies hesitate to invest in modern SCV technologies due to cost concerns, complexity or lack of expertise.

- Supplier and partner collaboration issues. SCV requires collaboration across multiple stakeholders, including suppliers, manufacturers, distributors and logistics providers.

To overcome these challenges, organizations must commit to investing in SCV systems, integrate supply chain data and foster collaboration across all supply chain partners.

Future trends

The future of SCV is driven by emerging technologies, automation, data intelligence and the following:

- AI-powered predictive analytics. AI will play a larger role in forecasting disruptions, optimizing routes and identifying supply chain inefficiencies.

- Digital twin technology. Digital twins -- virtual simulations of supply chain operations -- will enable businesses to test different scenarios and improve planning.

- IoT and smart logistics. IoT sensors and connected devices will enhance tracking accuracy, reduce theft and improve cold chain management.

- Sustainability and ethical sourcing. SCV will help organizations ensure ethical labor practices, track carbon footprints and meet environmental, social and governance goals.

- Autonomous supply chain operations. Automation, robotics and self-learning AI systems will revolutionize how goods are produced, stored and transported.

Supply chain visibility is a critical component of modern business operations. Companies that invest in SCV technologies, integrate real-time data and improve supply chain transparency will gain a competitive advantage in efficiency, risk management and customer satisfaction.

Weather events, geopolitical unrest and other disruptions are occurring more frequently. These techniques for supply chain resilience can help manage these challenges.