just-in-time manufacturing (JIT manufacturing)

What is just-in-time manufacturing (JIT manufacturing)?

Just-in-time manufacturing (JIT manufacturing) is a production model in which items are created to meet demand, not created in surplus or in advance of need. Organizations adopt the JIT approach to increase efficiency, reduce costs and speed up product delivery. To achieve these goals, however, they must eliminate the types of waste typically associated with manufacturing, such as overproduction, unnecessary wait times and excessive inventory -- only then can they implement an effective JIT strategy.

The history of JIT manufacturing

The JIT methodology, also known as the Lean production model, is commonly associated with manufacturers in post-World War II Japan. Faced with a lack of working capital and natural resources, Japanese companies had to incorporate lean, efficient business practices into their manufacturing processes. This meant building smaller factories and producing items in smaller batches, while paying close attention to the efficiency of their production processes.

Toyota was at the forefront of the JIT effort in Japan, implementing JIT practices so successfully that the company's approach became known as the Toyota Production System (TPS). According to TPS philosophy, manufacturers are susceptible to seven types of waste:

- Overproduction. More items are produced than are currently required by customers.

- Waiting. Items sit waiting for other processes to complete before production can continue forward.

- Inventory. The manufacturer has too much inventory on hand, requiring extra storage and management.

- Transportation. Materials or products are transported unnecessarily during the production process.

- Processing. Inefficient processing results in unnecessary efforts, equipment or time spent in production.

- Motion. Workers move inefficiently and unnecessarily during the production process.

- Defects. Defective products result in wasted time, materials and effort and can impact the company's reputation.

Toyota had a great deal of success eliminating these seven types of waste from its operations, which is why the company is often credited with bringing the JIT strategy to manufacturing. However, Henry Ford had already introduced similar concepts in his 1923 book, My Life and Work:

We have found in buying materials that it is not worthwhile to buy for other than immediate needs. We buy only enough to fit into the plan of production, taking into consideration the state of transportation at the time. If transportation were perfect and an even flow of materials could be assured, it would not be necessary to carry any stock whatsoever. The carloads of raw materials would arrive on schedule and in the planned order and amounts, and go from the railway cars into production. That would save a great deal of money, for it would give a very rapid turnover and thus decrease the amount of money tied up in materials.

Despite Ford's proclamations, however, it was not the Ford Motor Company that provided Toyota representatives with a JIT model in action. When the representatives toured plants in the United States in 1956, Ford had not yet fully implemented the JIT model. Instead, it was at Piggly Wiggly, the first self-service grocery chain in the U.S., where they discovered the model on which to base their own JIT system.

Implementing the JIT methodology

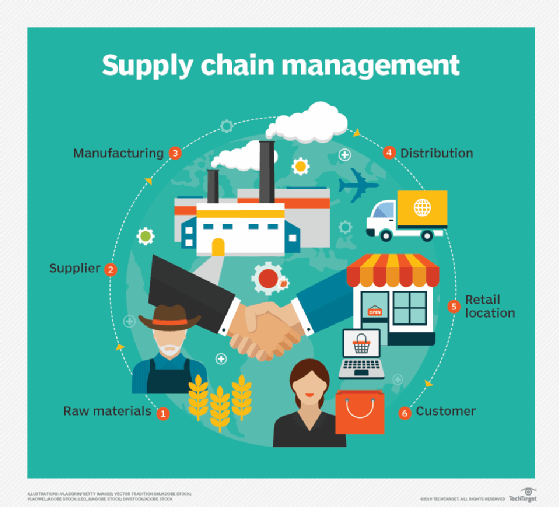

The JIT methodology requires that manufacturers establish strong relationships with suppliers and supply chain visibility to ensure that materials are delivered reliably and without interruption. Manufacturers must also implement standardized internal processes, with an emphasis on efficiency and effective communications. In addition, they must continuously look for ways to improve business processes and operations, no matter how well they currently work.

Through the careful implementation of JIT methodologies, manufacturers can reduce inventory levels, lower ongoing costs, increase product quality and achieve greater overall efficiency. However, even if a company does everything right, JIT manufacturing is not without risks. As the COVID-19 pandemic showed, JIT processes are highly susceptible to disruptions in the supply chain. If a manufacturer cannot get the material it needs to carry out production, its entire operation can be brought to a standstill.

Because of these risks, some companies have adopted -- or have stuck with -- just-in-case manufacturing (JIC manufacturing). With this system, they maintain large inventories to insure against supply chain disruptions or unexpected increases in demand for the product. However, this approach comes with significant costs for purchasing and maintaining that inventory. Going forward, manufacturers will likely need to find a balance between JIT and JIC manufacturing to effectively control overhead, while minimizing supply chain risks.

See also: supply chain planning, demand signal repository, demand shaping and Lean production.